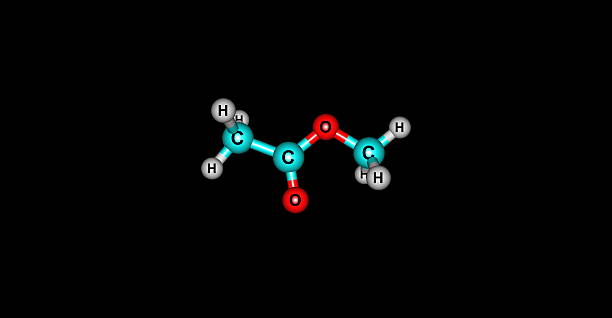

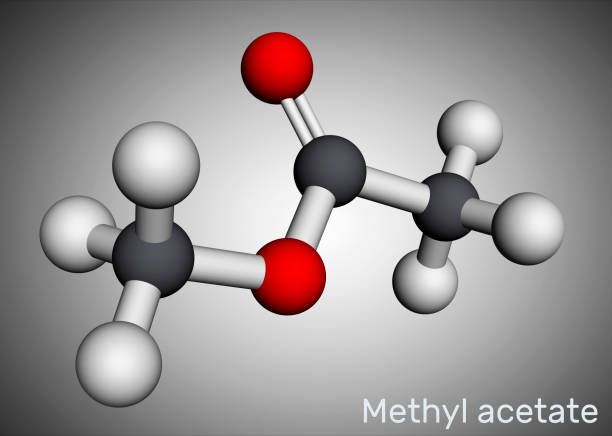

Methyl Acetate

Methyl acetate (CH3COOCH3), IUPAC name methyl ethanoate, is an ester and has a pleasant odor of glue. It is a good organic solvent which dissolves an array of resins, such as cellulose acetate, polyvinyl acetate, acrylics, epoxies, polyesters, etc. It is an organic solvent which can be used as a replacement of acetone in the production of paints, coatings, metal surface cleaners, adhesives, etc

- Overview

- Production

- Application

- Spesification

Overview

Methyl acetate (CH3COOCH3), IUPAC name methyl ethanoate, is an ester and has a pleasant odor of glue. It is a clear, colorless, and flammable liquid. It is soluble in most organic solvents, but partially soluble in water. It is a good organic solvent which dissolves an array of resins, such as cellulose acetate, polyvinyl acetate, acrylics, epoxies, polyesters, etc.

Methyl acetate has low toxicity, is readily biodegradable, VOC exempted, and not considered as a hazardous air pollutant, making it an environmental friendly solvent. It is an organic solvent which can be used as a replacement of acetone in the production of paints, coatings, metal surface cleaners, adhesives, etc. The following properties make it an ideal replacement for acetone:

- It’s evaporation rate is comparable to that of acetone;

- It has a higher flash-point compared to acetone;

- It is more hydrophobic than acetone;

- It has a very low maximum incremental value (MIR) compared to acetone;

- It is more cost effective than acetone.

Industrially, methyl acetate is manufactured by esterification of acetic acid with methanol. It is obtained as a by-product during the production of acetic acid, by carbonylation of methanol. It is also obtained as by-product during the production of purified terephthalic acid (PTA) and polyvinyl alcohol.

Production

Methyl acetate is industrially manufactured by the following four processes:

- Esterification of acetic acid with methanol.

The most prevalent method for manufacturing methyl acetate is via esterification of acetic acid with methanol in the presence of sulphuric acid or ion exchange resin as a catalyst. However, during this process, azeotropes of methyl acetate – water and methyl acetate – methanol are formed. Therefore, this process is carried out via reactive distillation to obtain high purity methyl acetate. - By-product during acetic acid production.

In this process methyl acetate is obtained as a by-product during the production of acetic acid via carbonylation of methanol in the presence of rhodium catalyst and methyl iodide promoter. Acetic acid, which is obtained by carbonylation of methanol, further reacts with methanol to produce methyl acetate. - By-product during purified terephthalic acid (PTA) production.

PTA is generally produced by the oxidation of para-xylene, using acetic acid as a solvent, in the presence of Cobalt-Manganese-Bromine catalyst system. During this process, methyl acetate is produced as a by-product along with PTA by oxidative decarboxylation of acetic acid. - By-product during polyvinyl alcohol production.

Industrially, polyvinyl alcohol is produced from vinyl acetate by a two-step procedure. First, vinyl acetate is polymerized to form poly vinyl acetate in an organic solvent such as methanol, and then, polyvinyl acetate dissolved in methanol is hydrolyzed to poly vinyl alcohol producing methyl acetate as a by-product.

Application

Methyl acetate is an organic solvent which can be used as a replacement of acetone in the production of paints, coatings, metal surface cleaners, adhesives, etc. Applications of methyl acetate are as follows:

Paints and coatings

Methyl acetate is a fast evaporating solvent which is used to produce a wide range of fast drying paints and coatings for wood finishing (lacquers), automotive applications, industrial applications, marine equipment’s and vehicles, cans, etc. Application of methyl acetate in paints and coatings is assisted by the fact that it has a VOC exempted status. It is also an ideal candidate to be used as a solvent in nail polish.

Surface cleaners

Methyl acetate can be used as a solvent in surface cleaners because of its fast drying and hydrophobic properties. Since methyl acetate evaporates at a fast rate, it doesn’t attract air contaminants to the cleansed surface. Moreover, the hydrophobic property of methyl acetate makes it suitable for cleaning metal surface prior to painting and preparing surface cleaners for marine applications and moisture sensitive equipments.

Other applications

Methyl acetate is also used as a solvent to produce fast sticking adhesives. Adhesives are produced by dissolving rubbers and resins in methyl acetate. When the adhesive is applied to a surface, methyl acetate evaporates at a fast rate, allowing the adhesive to harden and stick to the surface. Methyl acetate is also used in cosmetics and personal care products such as perfumes, nail polish, nail polish remover, etc.

Spesification

Product Identification

| CAS No. | : | 79-20-9 |

| Molecular Formula | : | CH3COOCH3 |

| Synonym | : | MeOAc, acetic acid methyl ester, and methyl ethanoate |

| H.S.Code | : | 2915.39.00 |

Methyl Acetate Specification

| Physical State | Liquid |

Odor | Pleasant odor |

Soluble | Most organic solvents, partially in water |

APPEARANCE | Colorless, clear from sediments |

Color, HU | Max. 100 |

Purity, % by wt | Min. 90.0 |

Water, % by wt | Max. 4.0 |

Methanol, % by wt | Max. 4.0 |

N-Propyl Acetate, % by wt | Max. 3.0 |

Acetic Acid, % by wt | Max. 1.0 |

Acetaldehyde, % by wt | Max. 1.0 |

Packing:

80 Drums @ 205 kg, 16.4 MT/FCL.